Packaging Solutions

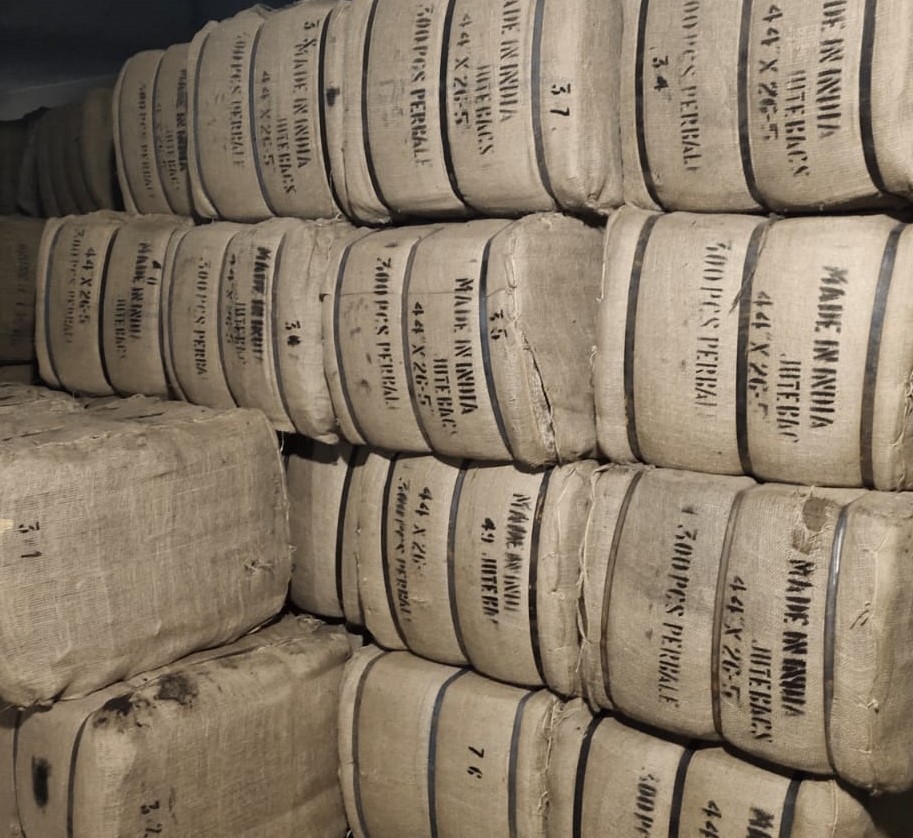

Jute Bags

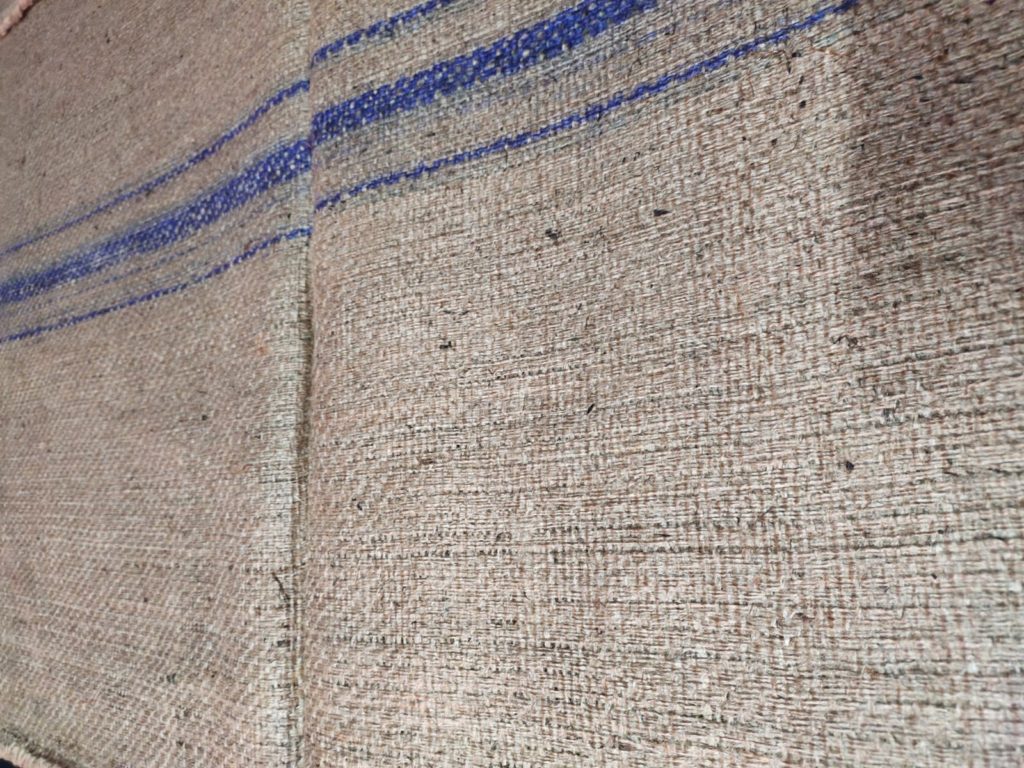

Our jute sacking bags are made of our own high-quality sacking fabric, available in plain and twill forms. Commonly used to pack cement, sugar, and other bulky items, our sacking bags are superior to synthetic sacking materials as they are biodegradable and breathable.

For packaging food material such as cocoa, coffee, grains, and potatoes, we offer high quality hydro-carbon free (HCF) food-grade sacking bags. These bags allow proper storage and transportation of these items, and help minimize food wastage. They are approved by leading users in Europe, Africa, and Latin America. Our food-grade bags are produced using rice bran oil (RBO) & Vegetable oil treated (VOC) technology, and conform fully to international specifications prescribed in IJO 98/01 and by the IOCCC. We provide a food-grade certificate issued by Cotecna/SGS for the bags that we ship.

Specifications of Jute bags we offer: Jute Bag- A Twill Available in Non-HCF & HCF quality with an option of custom printing, Plain or color strips. Jute Bag- B Twill Available in Non-HCF & HCF quality with an option of custom printing, Plain or color strips. Polypropylene (PP) bags Throughout the years, PP Woven Sacks have demonstrated their greatness in the packaging unit of several enterprises. Such sacks are known to be the toughest packaging bags, high in demand in the industries of sugar, grains, milling, and food. Woven Polypropylene bags: We feel pleasure to introduce ourselves as supplier, and exporter, which are used as packaging materials in different industries. Our PP Woven Sacks are flexible, high in strength, and durable in the packaging industry. These bags are an excellent solution to pack 30-50 KG of dry material. These bags are manufactured from polypropylene woven fabric which has superior strength and is less prone to punctures. These bags may come in laminated woven bags or non-laminated versions, depending on the material requirement. PP Woven small bags are used to package a wide variety of materials like animal feed, cement, ceramics, talk, seeds, and sands, etc. PP Woven Sacks/ Bags Some of the important factors of BOPP packaging are as below : Biaxially oriented Polypropylene bags (BOPP): BOPP stands for Biaxially Oriented Polypropylene. BOPP is a poly film that is applied as an additional layer to your woven polypropylene bags. It has been stretched in both directions for premium durability. We offer the best quality range of Biaxially Oriented Polypropylene Bags. BOPP bags are one of the most attractive packaging options in various Food/Chemical/Fertilizer industries. These bags can be used for various purposes specifically for the packaging of food products, confectionery items, etc. These bags are printed in multicolored from both sides and can be used both for storing and packing purposes. We are offering a wide range of bags that are made with fine quality materials and are available to our customers. These Bopp Bags have an alluring appearance and are used for packaging costlier products like pesticides, seeds, wheat flour, high-end chemicals, etc. They may also be used for secondary packaging of smaller 5-10kg bags. Important factors of BOPP packaging are as below : Laminated Paper Bags We are one of the leading suppliers of Laminated Paper Bags. We offer products that have optimum quality and durability. Our products are processed by using premium quality raw material that is procured from reliable vendors of the markets. These bags are strictly tested under the vigilance of our quality controllers to ensure the quality of our products. We manufacture a complete range of laminated paper bags according to customer requirements. We have a wide variety of products that cater to all your needs. Paper Laminated Bags are used for the packaging of products like chemicals, fertilizers, sugar, food grains, etc. In addition to this, these bags also retain product quality and ensure enhanced storage life. Laminated paper bags: We are a major polypropylene bag supplier & Exporter and here to help you choose what’s right for you. We have laminated paper bag options available for a wide range of industries. Types of Laminated Paper Bags: Vacuum Packing Bags Vacuum Bags are a 5 layer structure, which ensures complete protection of the products from any sort of damage. Nylon Polyamide based medium barrier Vacuum Bags is best suitable for products that demand a limited shelf life of 60to 12 months. The products that are highly oxygen-sensitive or require longer shelf life of up to 2 years are packed in High Barrier EVOH Vacuum Bags. Vacuum Bags (EVOH): We specialize in Vacuum Bags in various sizes which we customize as per the specifications of our clients. Vacuum Packing Bags Vacuum bags packaging using either only CO2 or mixture of CO2 and N2 flushing.